|

• Little impedance and little reactance drop.

• High flexibility for good working efficiency.

• High resistance to repeating kicks and bending caused by electro-magnetic force induced by welding current and welding operation, and accordingly long life.

• Excellent cooling effect even in continued welding operation.

• Easy check, replacement, and maintenance.

• Covering of good pressure resistance, heat resistance, and wear resistance.

• The kickless cable is consumable part and required to be inexpensive.

• Long cable life reduces cable cost per weld - the true measure of cable cost.

Secondary cables for portable Spot Welding Machine

1. This specification consult to JIS C 9318

2. Ours secondary cable mainly include Kickless cable and single conductor cable.

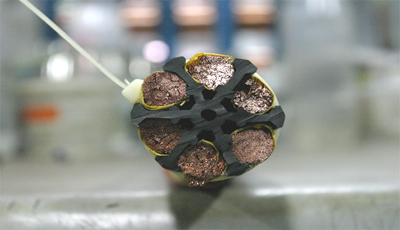

1) Kickless cable: A low-reactance water cooled flexible cable composed of 2 separate conductors insulated mutually and braided into a single hose.

2) Single conductor cable: A water cooled flexible,in which each of go-and-return path conductors is braided into a hose,usually making a set.

3. Specifiction

|

ITEM

|

CABLE SIZE

|

|

300 MCM (2X150MM2)

|

400 MCM (2X200MM2)

|

|

2.0M

|

2.4M

|

3.0M

|

2.0M

|

2.4M

|

3.0M

|

|

RESISTANCE (μΩ)

|

460

|

550

|

680

|

330

|

400

|

495

|

|

IMPEDANCE (μΩ)

|

465±10

|

556±10

|

686±10

|

333±15

|

404±15

|

500±15

|

|

REACTANCE (μΩ)

|

68

|

81

|

90

|

45

|

57

|

71

|

|

COOLING WATER FLOWING

|

6L/MIN

|

|

Dia. Of bare copper wire

|

φ 0.25mm

|

|

LIFE TIME

|

About 600000 spot welding at 12000A,10CYCLE(NORMALLY 4 MONTHES)

|

4. Cable Model:

A. Kickless cable model:

Usually,we have 3 kinds of cross section 150sqmm*2, 160sqmm*2and 200sqmm*2,the satandard length is 2.4m.Also,we can make different length cable accroding to clients’ needs.

B. Single conductor cable,Aid cable:

We have 150/160/180/200/250sqmm cross section cable, the length is according to customers' needs.

HTRF Cover Hose

|

MCM

Size

|

Outer

Diameter

|

Terminal

Diameter

|

|

300

|

2″

|

1-7/16″

|

|

400-450

|

2-1/4″

|

1-11/16″

|

|

500

|

2-7/16″

|

1-7/8″

|

|

650

|

2-9/16″

|

1-7/8″

|

The HTRF Cover hose was developed to combat the primary cause of water-cooled cable failure: wear through of the outer cover. Often a hose wears through due to abrasion on the welding equipment or production components. WATTEREDGE-UNIFLEX has developed a super high abrasion compound which can outlast other materials 40 to 1 against failure due to abrasion. This compound is integrated into the HTRF cover hose, which is available for all kickless cables and also for water cooled jumpers up to 600 MCM in size.

Also available is a high abrasion thin wall sleeve, which can be mounted over the standard kickless cable hose.

DC Cable / 500 and 650 MCM

|

Opposed polarity cables for high amperage, direct current applications.

These heavily reinforced, two conductor water cooled cables are primarily used on heavy duty spot welding stations for joining aluminum panels. This cable is designed to operate at welding currents typically in the range of 45,000 to 55,000 amps D.C.

Several design features maximize cable life and are exclusive to these WATTEREDGE-UNIFLEX cables:

Stranding is press welded to the terminal to provide the lowest possible electrical resistance properties and a virtually indestructible bond. (Patent # 4,640,982)

Opposed polarity for optimum efficiency.

High strength, high temperature teflon reinforced retaining rings throughout the entire cable length.

High pressure, impact resistant cover hose.

1/2″ or 3/8″ NPT water port

21/32″ diameter mounting hole |

|